Trex

Enterprises Career

(Updated May 2014)

I joined Trex Enterprises in 1994 when it was still

called ThermoTrex, a research subsidiary of Thermo Electron. A large laser program was just winding down,

but a collaboration with the University of Arizona was just beginning. That project sought to upgrade the

soon-to-be-disassembled Multiple Mirror Telescope with adaptive optics, with

follow-ons for the Large Binocular Telescope and a chance at designing the

Hubble Space Telescope replacement with a larger thin-mirror design. One common problem involved sensing the

position of a thin, flexible adaptive secondary. I proposed using an aluminum coating on the

rear surface of the mirror, in close proximity to a reference support. For this to work the thin aluminum coating

had to be conductive and easily accessible.

I put some silver epoxy on two edges of an aluminized mirror and showed

that the very thin coating would have sufficient conductivity. This mirror was in my desk for 20 years, until

I retired in May 2014.

Before the MMT was decommissioned, the astronomers

wanted to test some other ideas. Since I

was already familiar with tip-tilt systems, I helped design, build, and install

a system with six tip-tilt mirrors, one for each of the MMT primaries. These papers were presented at the first of

many SPIE conferences to come. Many

papers followed over the next few years, each describing an incremental

improvement of the adaptive secondary design or recent results. I was fortunate to start travelling

internationally, and found that, while sometimes difficult, the rewards more

than compensated the travel stresses.

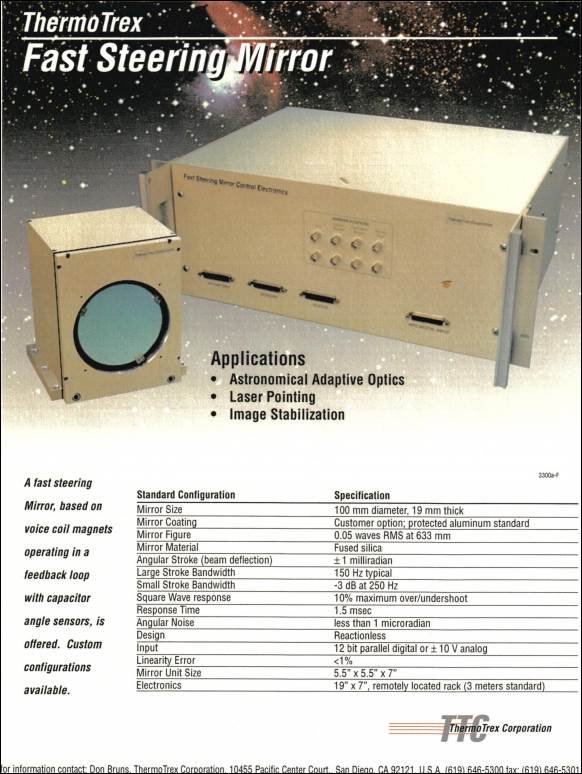

Based on my experience with voice coil actuators, I

developed and delivered a large fast steering mirror for the Italian National

Telescope. I used a flexible pivot and a dummy reaction mass, using either

capacitive or eddy current sensors to monitor the mirror position and provide

internal feedback.

ThermoTrex

attempted to commercialize a related system, and the fast steering mirror was

included in the Oriel products catalog.

I scaled the system to both larger and smaller mirrors.

All good things must come to an end, and so it was

with the large telescope projects.

Through contacts in the adaptive optics community, I learned of an

active optics project at the National Ignition Facility (NIF) that required 39

actuators per system, with the production potential of 200 systems. (The NIF

project, coincidentally, was led by a scientist with whom I briefly worked at

Hughes. He left Hughes shortly after I

arrived there, to start a laser isotope separation program at Lawrence

Livermore National Labs, and was eventually promoted to the top job at

NIF.) My approach in the proposal was

different from what the LLNL staff expected, with the potential to meet or

exceed all of the requirements. They

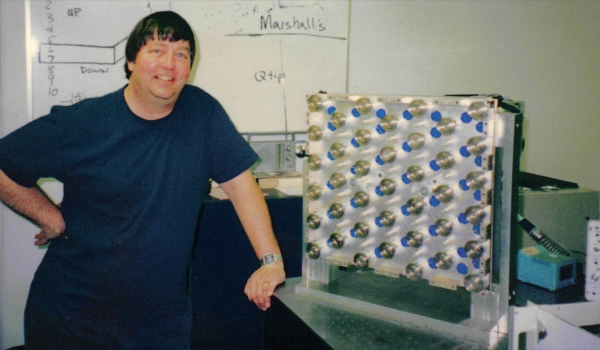

awarded Trex a nice contract in 1997. I

was the program manager, and worked endless hours solving some of the more difficult

problems. One detail was that voice coil

actuators were not strong enough to bend the thick mirror, and had a much

larger position range than necessary. I then

developed a novel electromagnetic actuator that had a high efficiency, since

most of the magnetic field was in iron, not air. I had a lot of these parts left over, and

saved one to keep in my personal collection.

Another innovation was to use vacuum pressure to

hold the mirror against the actuators, instead of bonding them to something

like a piezo-electric stack. This solved a number of problems, but

eventually led to the end of the program.

While the prototype met all of the requirements and was expected to far

exceed the lifetime requirements, the NIF facility was already under

construction, and the managers did not want to add a vacuum line to each of the

192 laser stations. Only in 2013 was NIF

fully functional, with all 192 lasers operating at the expected energy. Unfortunately, nuclear fusion was not

achieved, and the scientists there are trying to figure out what to do next.

I worked on a lot of various projects over my career

at Trex. These include RILC, a

long-distance laser-communication system, and GLINT, a Fourier-telescopy system based at our New Mexico offices. Some of these are telescope-related, and

included sophisticated optical configurations.

Some resulted in unclassified papers.

I also worked to help start three new spin-off

companies around 2000. One was “Silicon

Kinetics” which manufactures bio-molecular analysis equipment. The second was “Crossfiber”,

which manufactures high speed, fiber optic switching assemblies. The third was “Ophthonix”,

which manufactured custom eyeglasses with wavefront correction built into the

lenses, as an alternative to LASIK surgery.

That company had a lot of initial promise, and was based on some of my

key patents, but recently folded. One of

the co-founders happened to be a fellow graduate student with whom I worked and

vacationed with 20 years earlier! After

these excursions, I started working in astronomically-related fields again,

using small telescopes with military applications.

Working in a lab usually means nice working

conditions, but fielded experiments are often made in various

environments. I’ve crawled through

underground tunnels in Nevada, operated telescopes on windy mountain tops, set

up in hot and humid conditions near the ocean, and sometimes worked way past

midnight. Even in San Diego, the weather

can be cold enough to be uncomfortable, as shown in this example from 2007.

Laura and Tim are the two coworkers with whom I spent most of my time in the

last half of my career at Trex.

One major effort was to design a telescope that

could see stars during the day, as part of a celestial navigation system. The first efforts were successful, and led to

a wide variety of similar programs. One

prototype required three identical fixed telescopes, and I designed a support

block with angles such that each rhombohedral face

was fixed at 45° with respect to the horizon, a geometric figure I christened a

“Holtzen” parallelepiped, and used that term in the

patent.

Another application was to measure turbulence during

the daytime, using bright stars. I

designed an environmental enclosure for a larger telescope, and set it up in

Florida, just days before a hurricane.

The unit survived and was used to take the data that the customer needed

after the storm passed.

For the celestial navigation programs, test data one

time required a larger telescope.

Instead of building one from parts, or buying an assembled unit, Trex

was able to rent time on the famous 60” telescope at Mt. Wilson. I made the appropriate adapters for the

camera, and took data with Laura over two evenings.

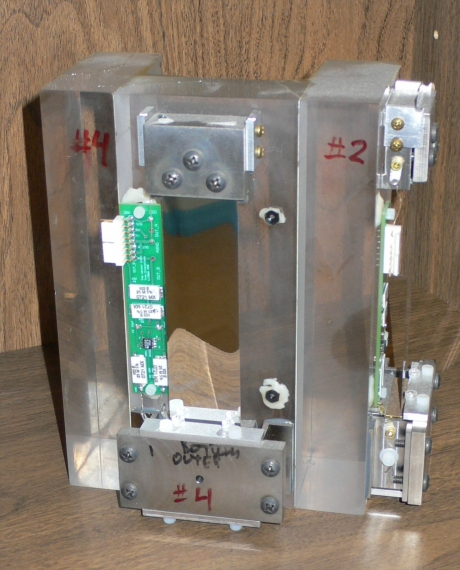

The last major instrument I designed at Trex was an

ultra-precision astrolabe. This unit

went through a few prototypes, and was tested at Trex, in my backyard, and at

Edwards AFB. Several units were built

and delivered, and more might yet be ordered.

This is probably the most sophisticated and precise instrument I

designed over my career. A paper

describing the key internal component is pending publication in the journal “Review

of Scientific Instruments”. The first

prototype was made from fused silica and titanium parts, but the final devices

are made from brass and aluminum. I will

continue to monitor the health of the first prototype in my home lab.

As a result of all of these programs, I’ve been

awarded 22 patents, with other applications still pending. A search of the US Patent database shows a

number of typographic errors, however.

The names of the companies associated with the patents include

“Thermotrex”, ThermoTrex”, “T-Rex”, “Trey Enterprises”, as well as Ophthonix and Trex Enterprises. I hope to continue to generate new patents in

my retirement.

Tesla

Coil Paper and High Voltage Projects

Laser

Experiences at Hughes Aircraft and Kaman Sciences

Stellar

Products Adaptive Optics

Weather

Station Papers and Remote Sensing Experiment