Laser

Experiences at Hughes Aircraft and Kaman Sciences

(Updated May 2014)

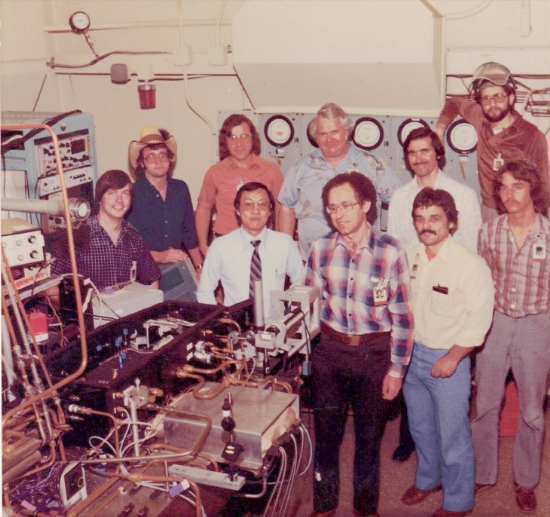

Right out of graduate school, I went from using

lasers as a spectroscopic tool to developing new lasers. Q-switched Nd:YAG lasers

operating near 1060nm were well-known, but my group leader wanted to develop

multi-color lasers for military use. One

technique was to use the Raman shift in some materials to generate new colors,

either directly from the infrared laser or from the green (frequency-doubled)

laser line. With my background in the

Raman effect from my graduate school days, I was a

good choice to lead the experimental effort.

One non-classified application was the development of a device that

could measure the heights of clouds at airports. Coincidentally, shifting the Nd:YAG laser line with methane gas resulted in a laser line at

an eyesafe wavelength near 1540 nm. The laser only pulsed once every 30 sec, so

the average power was very small. The

instrument was built and then installed near a runway at Dulles Airport. I saw it from a plane on one trip to

Washington DC a few years later, but we never built another unit.

Another military application required high average

power at a visible wavelength. We published

our results in a 1982 issue of the I.E.E.E. Journal of Quantum

Electronics. This source started with a

standard flash lamp-pumped laser and used non-linear mixing in a small crystal

to mix a Raman-shifted laser with some of the pump laser. Operating at a high repetition rate required

water cooling the pump laser and mechanically moving the methane gas. Shortly after this research, most of the

laser work was transitioned to the Hughes Malibu Research Labs. I stayed in El Segundo and transferred to another

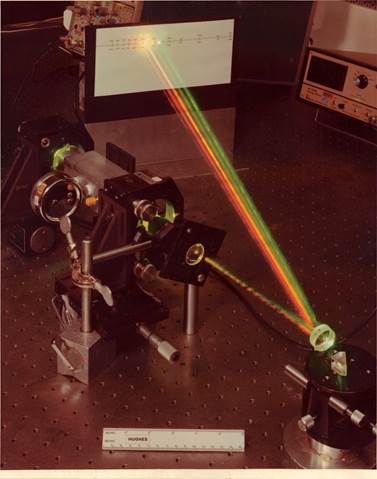

group. The photo here shows the colored

output, split by a prism. The colors are

shifted in multiples of one methane Raman transistion.

I was still involved in lasers and diagnostics. The biggest laser was a HF-DF gas laser,

which required an entire group of people to operate. Deuterium fluoride gas is poisonous and

expensive, so we used hydrogen fluoride for the experiments, at a slightly

different infrared wavelength. HF is

still dangerous, but we measured the cavity gain in short experiments, so we

didn’t use too much.

I completed my 9-year stint at Hughes Aircraft doing

work that cannot be described here in any detail. I learned about night vision devices, used CO2

lasers, and worked with a small group of employees in a managerial role. I learned that technical management was much

more suited to my talents than personnel management. After growing weary of the weather in Los

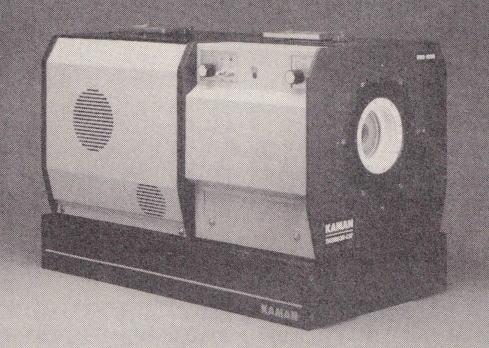

Angeles, I joined Kaman Sciences in Colorado Springs. My first task there was to develop the laser

transmitters for a high speed streak camera.

I designed the mechanics of the transmitters to allow small angular

adjustments in a stable, compact, fiber-coupled package. We used off-the-shelf near-infrared laser

diodes that were individually selected for high speed operation. We built a couple of these units, one for

testing in a microwave chamber in Huntsville, and others for underground installation

at a Nevada nuclear test site. I had fun

climbing through the tunnels, installing and testing the unit.

After this work, I transferred to a different group,

where I had my first experience with astronomical adaptive optics. Kaman was teamed with Lockheed to develop an

adaptive optics system for a military space shuttle experiment called

“Starlab”. Unfortunately, maybe because

of the residual schedule problems originating from the Challenger disaster a

few years earlier, the project was cancelled and most of the Kaman employees

working on the project were laid off. I

spent the next few years developing my own adaptive optics project for my

company I named “Stellar Products”.

Tesla

Coil Paper and High Voltage Projects

Stellar

Products Adaptive Optics

Weather

Station Papers and Remote Sensing Experiment